American Quality Roofers are expert at Metal Roof Installation. Our roofers on average have over 15 years of experience installing Metal Roofs. We do both residential and commercial metal roofing projects. For residential, homeowners mostly prefer 26 Gauge R-Panels. For commercial projects we use 24 Gauge panels. Both R-Panel and Standing Seam panels are popular with our commercial customers.

R-Panel is a multi-use wall and roof panel used primarily in pre-engineered metal building applications. R-Panel is also a popular choice for residential metal roofing. An optional purlin bearing leg (PBR) rests on purlins and provides support for fastening the panel lap. Fade and Chalk resistant Kynar 500 (PVDF) coatings provide building owners with a long-term, high performing panel that retains its original color and beauty year after year.

R-Panel testing, and classifications includes UL 580 Class 90 Uplift testing, ASTM E1680 air infiltration, ASTM E1646 water infiltration, and UL2218 Class 4 impact resistance.

Because R-Panel is very versatile and utilized on a wide variety of applications, it is available in many options. R-Panel is available with and without purlin bearing legs (PBR). Typically, PBR panels are utilized on roof applications because roofers appreciate the extra support when installing the panels to the roof substrate, or deck. Non PBR panels are more common for wall applications. Building owners can select R-Panel in wide range of Kynar 500® colors, or silicone-modified polyester coatings. R-Panel’s most popular steel substrate is 26 GA Galvalume®. Or select optional 22- or 24-gauge Galvalume® panels.

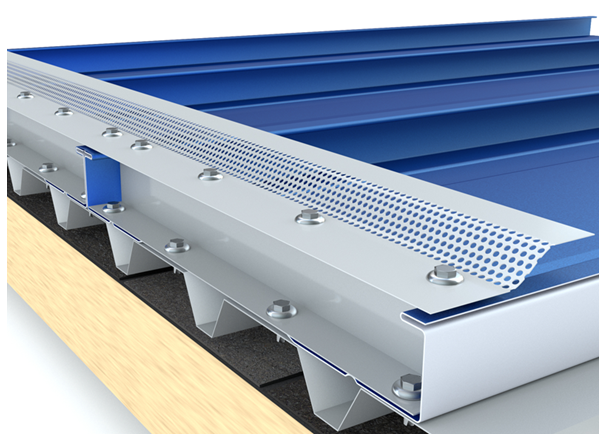

Standing seam systems are used for a wide range of applications and projects. These systems feature interlocking seams that connect panels, giving the roof a distinct, and attractive, appearance.

Furthermore, standing seam systems are manufactured from high-end steel or aluminum offering years of low-maintenance service life.

Standing seam systems attach to the substructure with concealed fasteners. Since there are no exposed screws with washers that can shrink or crack over time, they are considered a more weather-tight system than exposed fastener systems.

Standing seam systems allow expansion and contraction through either a clip or slotted flange. Conversely, exposed fastener systems are pinned which can result in the fastener hole elongating over time and allowing water penetration.

Standing seam panels typically offer a distinct vertical leg. This tall vertical leg can offer a nice shadow effect and the illusion of a flat pan in between the major ribs which many architects and building owners prefer.

We are available to help you 24 hours a day, seven days a week.

© 2023 American Quality Roofers.

![]()